Spezialbohrgetriebe Everything You Need to Know

In modern manufacturing and mechanical engineering, the Spezialbohrgetriebe (special drilling gearbox) plays a vital role. It is a highly precise tool designed for drilling requirements where standard drilling machines reach their limits. Whether in the automotive industry, aerospace, toolmaking, or metalworking – whenever complex drilling operations with maximum accuracy are required, a spezialbohrgetriebe becomes indispensable.

This blog will explain what a spezialbohrgetriebe is, how it works, its applications, benefits, and factors to consider before choosing one. At the end, you’ll also find answers to frequently asked questions.

What is a Spezialbohrgetriebe?

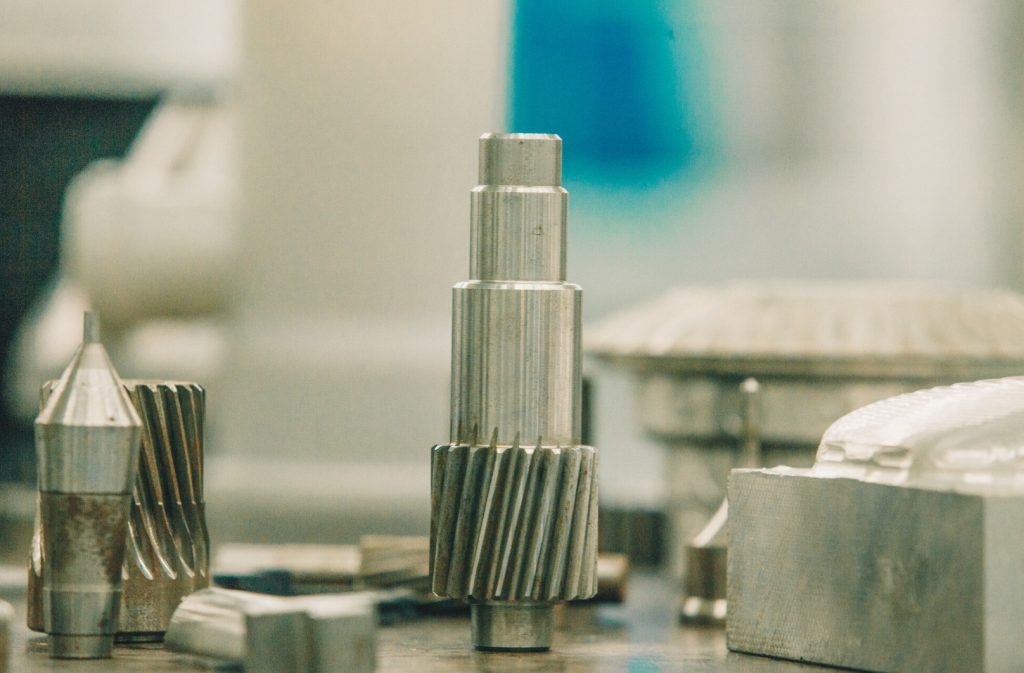

A spezialbohrgetriebe is a specially engineered drilling gearbox developed to make drilling processes more efficient, precise, and reliable. Unlike conventional gearboxes, these systems are designed according to specific requirements, providing tailored speed, torque, and transmission ratios.

Many spezialbohrgetriebe models are custom-made for industrial clients, ensuring seamless integration into existing machines and production lines.

Applications of Spezialbohrgetriebe

The versatility of the spezialbohrgetriebe makes it valuable across multiple industries. Some of the most common applications include:

1. Automotive Industry

In car manufacturing, precision drilling is required for engine blocks, gear components, and chassis parts. Spezialbohrgetriebe ensure accuracy and speed in mass production.

2. Aerospace Engineering

Aircraft and spacecraft parts must meet extremely tight tolerances. Spezialbohrgetriebe enable precise drilling in advanced materials like titanium, aluminum alloys, and composites.

3. Metalworking

From heavy machinery parts to precision components, spezialbohrgetriebe are essential when complex or multi-stage drilling is required.

4. Tool and Mold Making

High-precision drilling gearboxes allow manufacturers to create molds, dies, and tools with exceptional accuracy, ensuring consistent product quality.

Benefits of a Spezialbohrgetriebe

Investing in a spezialbohrgetriebe comes with numerous advantages:

- Precision – Enables exact drilling even in tough materials

- Customization – Designed according to specific customer requirements

- Durability – Built with high-quality materials for long service life

- Efficiency – Optimized speed and torque improve productivity

- Cost Savings – Reduces errors, material waste, and tool wear

How Does a Spezialbohrgetriebe Work?

A spezialbohrgetriebe is built with precision gear assemblies, bearings, and drive shafts. Its main function is to adjust rotation speed and torque so that the drill operates at the ideal performance level for each material.

Depending on the construction, it can deliver high torque at low speeds or high-speed rotation for fine drilling. Modern designs are modular, making it possible to adapt them easily to different machines and applications. Also Read: 1.5f8-p1uzt Texture

Key Factors When Choosing a Spezialbohrgetriebe

If you’re considering a spezialbohrgetriebe for your operations, here are the most important aspects to evaluate:

- Transmission Ratio – Depending on your torque and speed requirements

- Size & Weight – Must fit into existing production systems without issues

- Material Quality – Particularly important when working with hard alloys or composites

- Service & Maintenance – Availability of spare parts and after-sales support

- Manufacturer Expertise – Choose suppliers with proven experience and references

The Future of Spezialbohrgetriebe

As industries evolve toward automation and digitalization, the spezialbohrgetriebe is also becoming smarter. Future developments are likely to include: Also Read: Blog About @Pocketmemories Net

- IoT and Sensor Integration – Real-time monitoring of temperature, vibrations, and load

- Energy Efficiency – Lighter and more sustainable designs

- Advanced Materials – Stronger yet lighter construction for higher dynamics

- Automated Maintenance – Predictive systems that reduce downtime

FAQs About Spezialbohrgetriebe

What is the difference between a standard gearbox and a spezialbohrgetriebe?

A standard gearbox is general-purpose, while a spezialbohrgetriebe is custom-engineered for specific drilling applications, offering greater precision and efficiency.

Which industries benefit most from spezialbohrgetriebe?

They are widely used in automotive, aerospace, metalworking, and mold/tool making industries.

Can a spezialbohrgetriebe be integrated into existing machines?

Yes, many manufacturers offer custom-built solutions compatible with existing production systems.

How much does a spezialbohrgetriebe cost?

The cost varies depending on size, features, materials, and level of customization. Prices are usually higher than standard gearboxes due to the precision engineering involved.

What is the lifespan of a spezialbohrgetriebe?

With proper maintenance, these gearboxes can operate reliably for many years, even under heavy-duty industrial use.

Conclusion

The spezialbohrgetriebe is an indispensable component in modern industrial manufacturing. It ensures precision drilling, improves efficiency, and reduces costs by minimizing errors and material waste.

By choosing the right spezialbohrgetriebe tailored to specific requirements, companies can significantly boost productivity and product quality. As technology advances, these gearboxes will continue to evolve, integrating smarter systems that make industrial processes even more efficient.

For businesses that demand accuracy, durability, and performance, investing in a high-quality spezialbohrgetriebe is a smart long-term decision.